Into the Woods - Yosemite Clean Energy's 'Stump to Pump' Plans Rest on Local Partnerships | RBN Energy

California faces a broad set of challenges when it comes to reducing wildfires, which have been increasingly frequent and intense over the last decade — impacting the lives of those dealing with the threat, not to mention effects on the economy and environment. Separately, the state has been working to reduce transportation-related pollution and incentivize the development and use of a wide array of alternative fuels. Yosemite Clean Energy (YCE), which announced plans for its first plant site in late 2021, has an approach it says will not only make the state a cleaner and safer place but also foster the development of new transportation fuels. In today’s RBN blog, we look at YCE’s plans to turn wood waste into renewable fuels, how its unique “Stump to Pump” approach relies on partnerships with local communities, and the green hydrogen and renewable natural gas it plans to produce at sites across California.

As we noted in Space Oddity, a previous blog that examined ways to turn California’s biomass problem into an energy solution, the state had more than 60 biomass-fueled power plants operating as recently as the 1990s, but there are only about 30 direct-combustion plants running today, according to the California Energy Commission. The biomass sector has been hurt over the past decade by a combination of low natural gas prices, expiring power purchase agreements (PPAs), and the greatly expanded use of less-expensive wind and solar, as well as concerns about emissions from the traditional method of burning biomass.

With fewer alternatives to dispose of agricultural waste, some farmers have opted to just burn it instead, putting even more greenhouse gases (GHGs) into the atmosphere. The California Air Resources Board (CARB) voted last year to phase out all agricultural waste burning in the state’s Central Valley by 2025, so finding an outlet for that material is a priority. Overall safety is another concern. The biomass plants still operating in the state largely rely on the smaller trees and brush that can fuel wildfires, which have been especially frequent and severe recently, burning about 40% of the state’s national forest acreage over the past decade. But with fewer plants in operation, it has been difficult to successfully manage the state’s forests and reduce that fire risk. California’s total estimated biomass resource potential is 35 million bone dry tons (BDT — yes, that’s a real unit of measurement) of forest and farm wood waste per year, according to YCE, but the state’s existing plants can handle just a fraction of that, with the rest left to burn, decay and decompose — all of which releases GHGs — which means there’s a lot of potential to do more.

That’s where YCE’s plan comes into play. At its heart, the plan envisages a partnership with the local community — such as farmers, private forest owners and loggers — that would find a home for wood waste, help mitigate fire damage, save lives and property threatened by wildfires, create jobs and support the ecosystem. Under the YCE model, local owners and managers of wood waste would enter into a feedstock agreement with YCE (with an optional equity investment in the plant), deliver that wood waste to the plant site, earn a fee for that delivery, and then participate in the net profits of the plant. Each site would be capable of producing renewable natural gas (RNG) and green hydrogen for use as alternative transportation fuels, all while capturing any carbon dioxide (CO2) generated from that process. (Capturing the CO2 that would have otherwise been emitted makes the process carbon-negative.)

RNG is a term used to describe a biogas that has been upgraded to substitute for traditional natural gas. The biogas used to produce RNG can come from waste-management operations (such as California’s biomass industry), but can also come from municipal solid waste landfills, digesters at wastewater treatment plants, livestock farms, food production facilities and organic waste management operations. Green hydrogen is produced by splitting water into hydrogen and oxygen via electrolysis powered by renewable energy (see Help!, Part 2). When it is used, it emits no exhaust, only water.

Dual-Bed Gasification

The technology that YCE plans to utilize is designed to produce carbon-negative fuels from biomass at a commercial scale, using a system that does not include burning or the use of any water inputs or outputs. It all starts with what the company refers to as dual-bed gasification, a technology provided by Aichernig Engineering of Vienna, Austria, that was originally developed at the Vienna University of Technology. YCE says the technology has been used at a commercial scale in Europe since 2003, with more than 100,000 hours of run time.

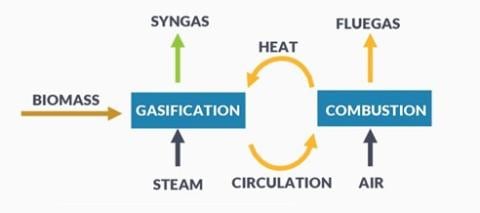

The system is comprised of two interconnected sections (blue rectangles in Figure 1). In the gasification section, the woody biomass is reacted with high heat and steam without oxygen to produce synthesis gas, or syngas, which is a mixture of carbon dioxide (CO2) and hydrogen. The char from the gasification section is fed into the combustion section, where it is reacted with air and oxygen to generate heat (which is fed back into the gasification system) and fluegas. Both sections are connected by fluidized beds.

Figure 1: Diagram of the Dual-Bed Gasification Process. Source: Yosemite Clean Energy

Once the syngas is produced in the gasification section, it is put through a multi-stage process that involves gas processing, purification and separation. From there, the syngas can be processed into green hydrogen or RNG, using technologies widely available in the U.S., supplied by companies such as Air Liquide or Chart Industries, with the CO2 captured separately. (The CO2 from the fluegas produced in the combustion section would also need to be captured.)

Target Markets and End Uses

As noted above, there’s no shortage of biomass available, but how much material could YCE’s plants use, and how much green hydrogen and RNG could they produce? Let’s start with the feedstock needed to run YCE’s first plant, planned for Oroville, CA, with commissioning to start in 2024 and production beginning in 2025. Oroville is in California’s Central Valley, the state’s most productive agricultural region, about 65 miles north of Sacramento. That plant would consume about 90,000 BDT over the course of a year, or nearly 250 BDT/d. YCE said the Oroville site is in the third stage of front-end engineering and design work and is working to get permit approval by January 2023, with a final investment decision (FID) to follow soon after.

The Oroville site would be able to produce about 13,000 kilograms per day (kg/d; 4,745 metric tons per year) of green hydrogen and 31,000 kg/d of RNG, which YCE says would be used as transportation fuels. Combined, that would provide the energy equivalent of more than 6.5 million diesel gallons, or what YCE says is enough to fuel 260 heavy-duty fuel-cell trucks each day. YCE envisions a series of its own fueling stations/truck stops spread across the state and has identified Class 8 trucks — including some of the largest rigs on the road, with gross vehicle weight of more than 33,000 pounds — and municipal bus fleets as its near-term customers.

Figure 2: Cummins’s Class 8 Hydrogen Truck. Source: Cummins

The RNG and green hydrogen produced by the plant would also be eligible for credits under California’s Low Carbon Fuels Standard (LCFS), which was adopted in 2009 and implemented in 2011 with the initial goal of lowering the carbon intensity (CI) of the state’s transportation fuels by at least 10% by 2020. The regulation was amended to include CI-reduction benchmarks of 20% through 2030. CI is a measure of the lifecycle GHG emissions associated with producing, distributing and consuming a fuel, and is measured in grams of CO2 equivalent per megajoule (gCO2e/MJ). The lower the CI the fuel achieves, the greater the LCFS credit. For example, CARBOB, the standard grade of gasoline in California, has a target CI score of about 90 in 2022, according to the California Air Resources Board.

YCE says its green hydrogen would have a CI of minus 56, with RNG being scored at minus 47, under the state’s CA-GREET3.0 Model, meaning they would generate credits equal to the difference in CI score for gasoline. That would be 146 credits for green hydrogen and 137 for RNG, based on a CI score of 90 for gasoline. YCE’s products could be very beneficial because companies with LCFS deficits must retire a number of credits from their credit account to balance their deficit. If they haven’t generated enough credits to meet their compliance obligation, they must purchase credits from other parties. (For more on California’s Low Carbon Fuel Standard, check out Come Clean, Part 2.)

Each of YCE’s plants would capture and sequester more than 60,000 metric tons (MT) of CO2 each year. YCE says the goal is to dispose of it via carbon capture and sequestration (CCS), which requires a Class VI well for deep geologic storage, with potential sequestration sites near Sacramento and Modesto, CA. Some of the CO2 could also be used in enhanced oil recovery (EOR) near Bakersfield, CA. In EOR, the captured CO2 is used to boost production of crude oil and natural gas in existing fields, with the CO2 ultimately being sequestered underground. CO2 that is disposed of via CCS or EOR would be eligible for the federal 45Q tax credit, which is available for a variety of carbon-capture projects and creates a tax credit for CO2 that is permanently sequestered. The credit for EOR is $25.15/MT this year, but jumps to $32.54/MT in 2025, when the first YCE plant would be in operation. The CCS credit is $37.85/MT this year, climbing to $46.96/MT by 2025. (For more on carbon-capture technology and the 45Q tax credit, see our Way Down in the Hole series.)

If you’re keeping score at home, all told, YCE would be generating money from the sale of RNG and green hydrogen for use as transportation fuels, and local farmers, private forest owners and loggers would be compensated for supplying the necessary biomass, while also potentially sharing in the plant’s net profits.

With the Oroville project moving forward and policies in place to incentivize alternative fuels and carbon capture, YCE believes the strength of its local partnerships and the reliability of the dual-bed gasification system will help it put a dent in California’s biomass problem, improve fire safety in the state and speed the transition to renewable fuels.

“Into the Woods” is a musical with music and lyrics by Stephen Sondheim and book by James Lapine. It was first presented at the Old Globe Theatre in San Diego in 1986 and made its Broadway premiere in 1987. The show won three Tony Awards in 1988. “Into the Woods” presents the plots of several Grimm Brothers fairy tales, examining various consequences of the characters’ wishes and adventures. The musical has been produced many times over the years since its debut, and in 2014 Disney released a film adaptation produced by Rob Marshall that grossed over $213 million worldwide.

A soundtrack album, Into the Woods (Original Motion Picture Soundtrack), was recorded to coincide with the film release during 2013-14. It featured vocals from the film’s ensemble, including Meryl Streep, Emily Blunt, James Corden, Tracey Ullman and Johnny Depp. Recorded at Angel Recording Studios, Air Lyndhurst Studios, and British Grove Studios in London, the album was produced by Mike Higham, Rob Marshall and John DeLuca. Released in December 2014, it went to #2 on the Billboard Soundtrack Albums and #8 on the Billboard 200 Albums charts.

A second Broadway revival of “Into the Woods” is scheduled to begin at the end of June 2022 at the St. James Theatre in New York City.